- Cable wire Coiling Binding

- Tape winding machine

- Semi-auto strip twist brush

- Wire cutting stripping machine

- Semi-auto crimping machine

- Stripper crimper Blades

- Terminal Tensile Tester

- Cut-off machine

- Cable labeling machine

- Strapping banding tool

- Terminals/connector/Plugs

- Automated Tape Dispenser

- Automatic Crimp Machine

- Terminal Crimping tools

- Auto Wire feeder

- Automatic soldering machine

- Nylon Cable Tie Machine

- Injection molding machine

- Brazing welding machine

- Screw fastening machine

- Power cord crimping machine

- Wire harness tester

- Glue Dispensing Robot

- Wiring harness Packing materials

Home > Cable Wire Coiling Binding > Auto Coiling Tying Machine > Small 8 Type Single Tie Type Automatic Winding And Tie Machine WPM-RT-81S

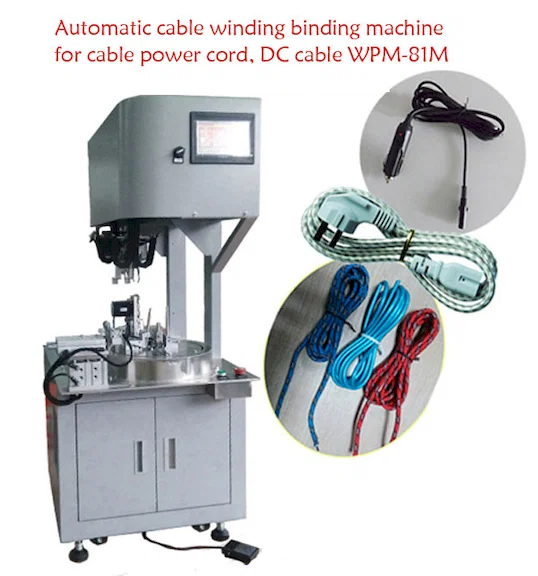

Small 8 type single tie type automatic winding and tie machine WPM-RT-81S

- Model No: WPM-RT-81S

- Small 8 type single tie type automatic winding and tie machine WPM-RT-81S

Technical parameters:

Suitable for AC/DC/USB cable

Winding appearance small 8-figure single cable tie

Applicable line length ≤3 m(depending on the line of sight)

Applicable wire diameter ≤ φ 4 mm

The spacing of winding is 45-80mm

Binding diameter ≤20 mm

The head length is 0-130 mm

Tail length >0 mm

Production efficiency 1800PCS /h (1-meter line length, 3 turns, outcrop, and outcrop)

Applicable binding tape-coated iron core ≤ 7.5kg/roll

Applicable pressure 0.55-0.65Mpa

Applicable voltage 220V 50Hz

Machine power ≤2800W

The machine size is about 1040L*720W*1540H mm

The weight of the machine is about 210KG - Inquiry now

Detailed description

Small 8 type single tie type automatic winding and tie machine WPM-RT-81S

Technical parameters:

Suitable for AC/DC/USB cable

Winding appearance small 8-figure single cable tie

Applicable line length ≤3 m(depending on the line of sight)

Applicable wire diameter ≤ φ 4 mm

The spacing of winding is 45-80mm

Binding diameter ≤20 mm

The head length is 0-130 mm

Tail length >0 mm

Production efficiency 1800PCS /h (1-meter line length, 3 turns, outcrop, and outcrop)

Applicable binding tape-coated iron core ≤ 7.5kg/roll

Applicable pressure 0.55-0.65Mpa

Applicable voltage 220V 50Hz

Machine power ≤2800W

The machine size is about 1040L*720W*1540H mm

The weight of the machine is about 210KG

Main components:

Cylinder: Yadeke cylinder and solenoid valve

Motor: Winding main servo motor 1500W Turbot

Motor: take line translation servo motor Turbot 750W

Motor: Twisted tie belt 57 stepper motor thunder race

Motor: Spit tie belt 57-step motor thunder race

Motor: storage tape motor 6W

Slide block: take line translation double slide block

PLC: vigor

Screen: Dimension control 7"

Power supply: clear weft

Frame: the iron frame is painted blue and white

Wire grab/twisting claw/lower claw Material: stainless steel

Drive system: high-reliability servo system, a control system for the high-speed stable industrial controller and system software, Chinese and English bilingual version.

Features:

Suitable for USB/DC/AC power supply, with the option to retain both ends or leave one end open. Additionally, it features programmable logic controller (PLC) control and a bilingual man-machine interface.

1. the new style. high matching. around the small figure of 8. tie a tie;

2. suitable for USB/DC/AC line. can leave the head and tail. head and tail. leave the head and tail;

3. winding motor adopts 1500W servo. full power. more stable;

4. take line translation motor 750W servo. eliminate step loss phenomenon and demagnetization problem of stepping motor. translation is more stable;

5. the top transparent chassis. pipeline layout and quality at a glance. high-grade atmosphere. three sides + top four sides can be disassembled. convenient maintenance;

6. independent power distribution cabinet. can be removed as a whole. electrical lines standard. neat. standard. convenient maintenance;

7. the bearing capacity of the tie belt can reach 7.5kg. reducing The time of changing the tie belt. and improving work efficiency;

8. A separate button is added to the structure of the spit tie belt. which is more convenient for installation and debugging;

9. rubber band under the claw structure optimization. make rubber band more wear resistance. installation and debugging more convenient,

10. the barometer upgrade. can automatically filter. drainage;

11. aluminum plate. conversion plate. fully upgraded into steel material. the machine is more durable;

12. The connection structure of the twisting claw. taking claw and lower claw is made of stainless steel. which is more stable and beautiful.

13. coil structure upgrade. less noise. more stable;

14. the production efficiency can reach 1800 pieces/hour. saving labor;

15. easy to operate. easy to debug. easy to maintain;

16. small size. does not occupy the place. save the rent;

17. humanized design. reduce the fatigue intensity of staff;

18. Programmable logic controller (PLC) control. Bilingual man-machine interface control;

Small 8 type single tie type automatic winding and tie machine WPM-RT-81S

Technical parameters:

Suitable for AC/DC/USB cable

Winding appearance small 8-figure single cable tie

Applicable line length ≤3 m(depending on the line of sight)

Applicable wire diameter ≤ φ 4 mm

The spacing of winding is 45-80mm

Binding diameter ≤20 mm

The head length is 0-130 mm

Tail length >0 mm

Production efficiency 1800PCS /h (1-meter line length, 3 turns, outcrop, and outcrop)

Applicable binding tape-coated iron core ≤ 7.5kg/roll

Applicable pressure 0.55-0.65Mpa

Applicable voltage 220V 50Hz

Machine power ≤2800W

The machine size is about 1040L*720W*1540H mm

The weight of the machine is about 210KG

Main components:

Cylinder: Yadeke cylinder and solenoid valve

Motor: Winding main servo motor 1500W Turbot

Motor: take line translation servo motor Turbot 750W

Motor: Twisted tie belt 57 stepper motor thunder race

Motor: Spit tie belt 57-step motor thunder race

Motor: storage tape motor 6W

Slide block: take line translation double slide block

PLC: vigor

Screen: Dimension control 7"

Power supply: clear weft

Frame: the iron frame is painted blue and white

Wire grab/twisting claw/lower claw Material: stainless steel

Drive system: high-reliability servo system, a control system for the high-speed stable industrial controller and system software, Chinese and English bilingual version.

Features:

Suitable for USB/DC/AC power supply, with the option to retain both ends or leave one end open. Additionally, it features programmable logic controller (PLC) control and a bilingual man-machine interface.

1. the new style. high matching. around the small figure of 8. tie a tie;

2. suitable for USB/DC/AC line. can leave the head and tail. head and tail. leave the head and tail;

3. winding motor adopts 1500W servo. full power. more stable;

4. take line translation motor 750W servo. eliminate step loss phenomenon and demagnetization problem of stepping motor. translation is more stable;

5. the top transparent chassis. pipeline layout and quality at a glance. high-grade atmosphere. three sides + top four sides can be disassembled. convenient maintenance;

6. independent power distribution cabinet. can be removed as a whole. electrical lines standard. neat. standard. convenient maintenance;

7. the bearing capacity of the tie belt can reach 7.5kg. reducing The time of changing the tie belt. and improving work efficiency;

8. A separate button is added to the structure of the spit tie belt. which is more convenient for installation and debugging;

9. rubber band under the claw structure optimization. make rubber band more wear resistance. installation and debugging more convenient,

10. the barometer upgrade. can automatically filter. drainage;

11. aluminum plate. conversion plate. fully upgraded into steel material. the machine is more durable;

12. The connection structure of the twisting claw. taking claw and lower claw is made of stainless steel. which is more stable and beautiful.

13. coil structure upgrade. less noise. more stable;

14. the production efficiency can reach 1800 pieces/hour. saving labor;

15. easy to operate. easy to debug. easy to maintain;

16. small size. does not occupy the place. save the rent;

17. humanized design. reduce the fatigue intensity of staff;

18. Programmable logic controller (PLC) control. Bilingual man-machine interface control;

Related products

link : cablecutting.net xmjw.ltd

- Categories

- Cable wire Coiling Binding

- Tape winding machine

- Semi-auto strip twist brush

- Wire cutting stripping machine

- Semi-auto crimping machine

- Contact Us

sales@cablecutting.net

sales@cablecutting.net kevin201166

kevin201166 +86-18965153335

+86-18965153335

- Copyright @ 2003-2023 XIAMEN JINGWEI TECHNOLOGY CO., LTD.

- E-mail sales@cablecutting.net npsales@126.com

- Contact: Mr. Kevin, Ms. Donna

- Tel:+86-0592-8628902 Mobile:+86-18965153335 Skype: kevin201166 Fax:+86-0592-6065010