WPM-500C Automatic Wire Pre-Feeder Machine - Robust and Reliable Wire Delivery for Demanding Harness Production

Headline: Maximize

Uptime and Efficiency with the WPM-500C Automatic Wire Pre-Feeder

Machine: Heavy-Duty, Versatile, and Designed for Seamless Wire Harness

Production

Introduction:

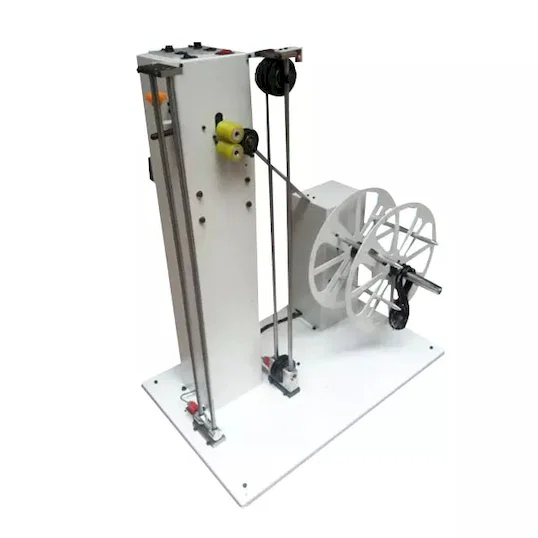

For wire harness manufacturers facing demanding production schedules and diverse wire handling needs, the WPM-500C Automatic Wire Pre-Feeder Machine provides a robust and reliable solution. This advanced Automatic Wire Feeding Machine, also known as a Wire Pay-off Stand or Wire and Cable Feeding Machine,

is engineered for heavy-duty performance and versatile wire spool

handling. Designed for seamless integration into your automated wire

harness production line, the WPM-500C ensures a consistent and

controlled wire supply, minimizing downtime, enhancing efficiency, and

providing a solid foundation for your entire wire processing workflow.

Key Features and Benefits: Heavy-Duty Construction, Versatile Wire Handling, and Automated Reliability

The

WPM-500C Automatic Wire Pre-Feeder Machine is built for demanding

industrial environments, offering a comprehensive set of features

designed to optimize your wire handling and deliver superior results:

-

Heavy-Duty Design for Robust and Reliable Performance: Experience unwavering performance even under demanding workloads. The

WPM-500C is engineered for robust and reliable operation, built to

withstand the rigors of continuous use in busy wire harness production

facilities. Its heavy-duty construction ensures long-lasting performance

and minimizes downtime, providing a dependable foundation for your

automated wire processing line.

-

Automated Wire Pay-off with Integrated Gas and Electrical Systems: Streamline your wire feeding process with fully integrated automation. This machine features automatic wire pay-off driven by integrated gas and electrical systems.

This seamless integration ensures smooth and controlled wire delivery,

eliminating manual wire handling and maximizing efficiency in your wire

harness production workflow.

-

Built-in Brake Function for Precise Wire Tension Control: Guarantee consistent wire tension and prevent wire handling issues. The WPM-500C incorporates a built-in brake function that provides precise control over wire tension during the feeding

process. This controlled tension prevents wire slack, tangling, and

over-spooling, ensuring a smooth and consistent wire supply to your

downstream processing equipment and minimizing potential disruptions to

your production line.

-

Versatile Compatibility for Most Wire Harness Processing Needs: Adapt to a wide range of wire harness manufacturing requirements with a highly versatile machine. The WPM-500C is suitable for most wire harness processing needs,

making it a valuable asset for diverse production lines. Whether you

are using fully automatic crimping machines, wire stripping machines, or

other harness assembly equipment, this pre-feeder machine provides a

reliable and adaptable wire supply.

-

Small Footprint and Easy to Move for Optimized Workspace Utilization: Maximize your valuable floor space and enjoy flexible equipment placement. The machine's small footprint allows for easy integration into existing workstations and production

lines, even in facilities where space is limited. Furthermore, its

design allows it to be easy to move, providing flexibility in reconfiguring your production line layout as needed and optimizing your workspace efficiency.

-

Handles Large Diameter Cables - Up to 10MM: Process a wide range of wire sizes, including larger gauge cables. The WPM-500C is designed to handle cables up to 10MM in diameter,

accommodating a broad spectrum of wire types commonly used in wire

harness manufacturing. This expanded diameter compatibility ensures the

machine can be used for diverse applications, from delicate signal wires

to larger power cables.

-

High Load Capacity for Extended Production Runs: 35KG Rated Load: Minimize downtime for wire spool changes and maximize continuous operation. The WPM-500C boasts a rated load capacity of 35kg,

allowing it to handle substantial wire spools. This high capacity

reduces the frequency of spool changes, enabling longer, uninterrupted

production runs and improving overall efficiency in high-volume wire

harness manufacturing environments.

-

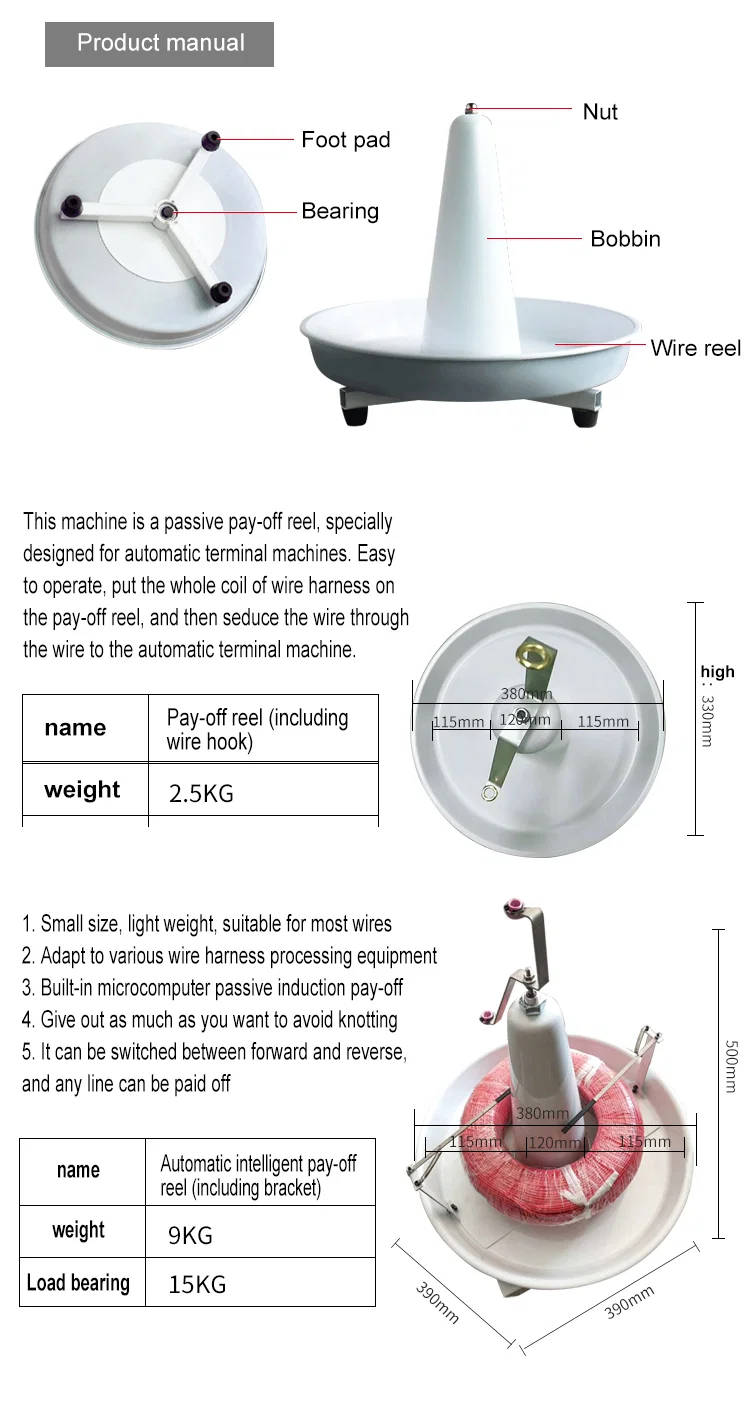

Broad Coil Compatibility - Accommodates Various Inner and Outer Diameters: Adapt to different wire spool formats and sizes commonly used in the

industry. The WPM-500C is designed to handle a wide range of coil

dimensions:

-

Coil Inner Diameter (Inner Hole Diameter): 85-320mm, accommodating various core sizes.

-

Outer Diameter of Outer Wire (Outer Ring Diameter): Within 380mm, handling larger diameter wire spools.

-

Wire Thickness: Up to 120mm or less, accommodating a significant amount of wire on each spool.

This

broad coil compatibility ensures the machine can be used with a wide

variety of wire spools commonly available in the market, simplifying

material procurement and ensuring seamless integration into your

existing supply chain.

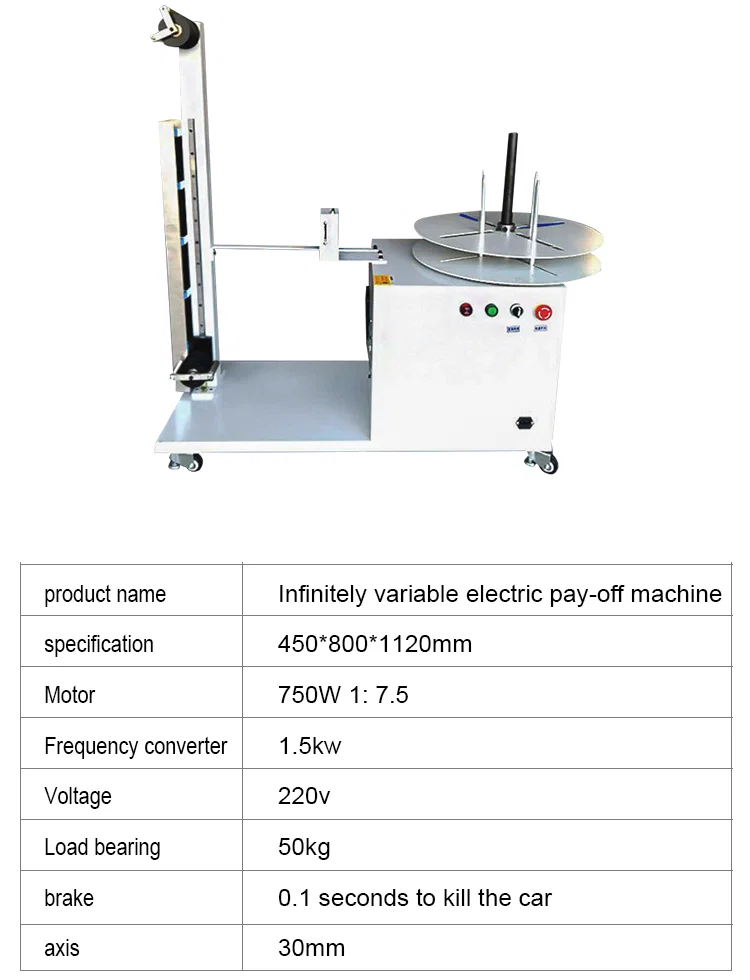

Technical Specifications (Model WPM-500C):

| Model | WPM-500C |

| Weight | 50kg |

| Rated Load | 35kg |

| Coil Inner Diameter (Inner Hole Diameter) | 85-320mm |

| Outer Diameter of Outer Wire (Outer Ring Diameter) | Within 380mm |

| Wire Thickness | 120mm or less |

| Cable Diameter Compatibility | Up to 10MM |

| Integration | Gas and Electrical Integration |

| Operation | Automatic Wire Pay-off, Brake Function |

| Compatibility | Fully Automatic Wire Harness Processing Machines |

| Mobility | Easy to Move |

| Footprint | Small |

Applications:

The WPM-500C Automatic Wire Pre-Feeder Machine is an essential component for optimizing wire handling and efficiency in:

-

High-Volume Wire Harness Manufacturing: Streamlining wire feeding for automated cable harness assembly lines in various industries.

-

Automotive Wire Harness Production: Meeting the demanding volume and reliability requirements of automotive wiring systems.

-

Appliance Wire Harness Assembly: Ensuring a consistent wire supply for efficient appliance wiring harness manufacturing.

-

Industrial Equipment Wiring: Providing robust and reliable wire feeding for heavy-duty industrial machinery wiring systems.

-

Any

wire processing facility seeking a heavy-duty, versatile, and automated

wire pre-feeding solution for large wire spools and diverse wire types.

Conclusion:

The WPM-500C Automatic Wire Pre-Feeder Machine is a robust and reliable investment for businesses seeking to optimize

their wire harness production processes and achieve superior efficiency

and quality. Its heavy-duty design, versatile wire handling

capabilities, automated operation, and user-friendly mobility make it an

invaluable asset for modern wire harness manufacturing facilities.

Upgrade your wire handling system today with the WPM-500C and experience

the benefits of truly automated and reliable wire pre-feeding for

demanding production environments.Okay, please provide the content you

would like me to use for the product descriptions. I will use that

information to write detailed and SEO-friendly product descriptions in

English, without including any SEO explanations, and focusing on being

beneficial for Google indexing and user readability. I'm ready when you

are! Just paste the content here.