Elevate

Your Electronic Assembly with the High-Precision Desktop Automatic Hot

Melt Glue Dispensing Machine: Durable, Easy-to-Use, and Engineered for

Accuracy

Introduction:

In

the intricate world of electronics manufacturing, precision and

reliability in adhesive application are crucial for product quality and

long-term performance. Introducing the Desktop Automatic Hot Melt Glue Dispensing Machine, a cutting-edge solution specifically designed to meet the exacting demands of the electronics industry. This advanced Automatic Glue Dispensing Machine delivers unparalleled accuracy, durability, and ease of operation,

ensuring consistent and flawless adhesive application for bonding,

filling, sealing, and coating tasks. Say goodbye to inconsistent manual

dispensing and embrace the future of automated precision, tailored for

the unique needs of electronic component assembly and production.

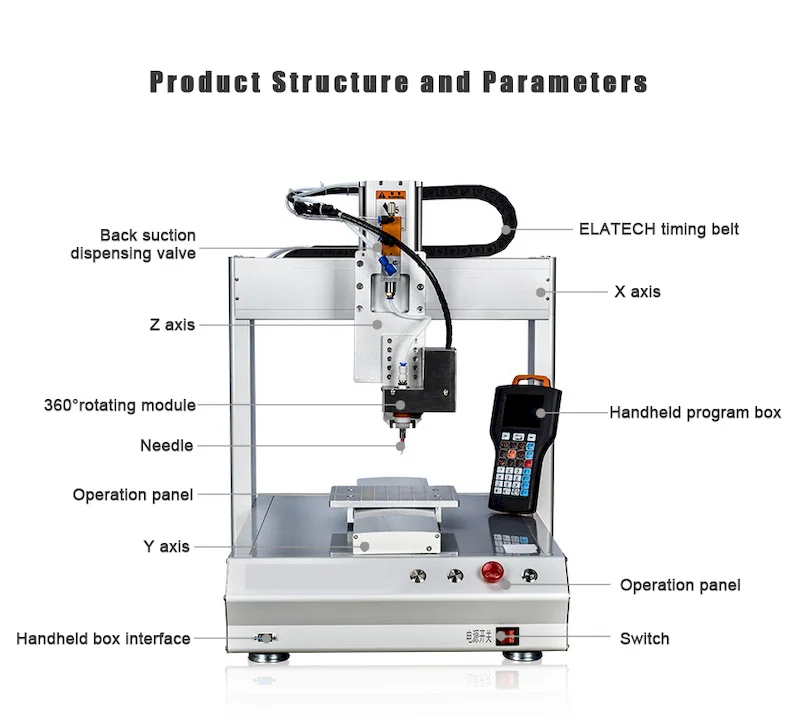

Key Features and Benefits: Precision, Durability, and User-Centric Design for Electronic Manufacturing

This

Melt Glue Dispensing Machine is meticulously engineered for superior

performance and ease of integration within electronic manufacturing

environments, offering a comprehensive suite of features designed to

optimize your adhesive application process:

-

Unrivaled High-Precision and Long-Lasting Durability: Built to deliver consistent and reliable performance over extended periods. This machine utilizes a precision valve spool at its core, ensuring accurate and repeatable dispensing volumes down to 0.01ml. Incorporating high-end accessories and constructed with wear and corrosion-resistant materials, this dispenser is engineered for long working life, minimizing downtime and maximizing your return on investment.

-

Expertly Crafted with Professional Technology and Stable Quality: Benefit from decades of industry expertise and meticulous craftsmanship. Built upon rich industry production experience, this machine is assembled by technically skilled professionals. Its tight structure, professional polishing, and rigorous quality control processes guarantee stable and consistent quality, providing you with a reliable and dependable dispensing solution you can trust for critical electronic assembly tasks.

-

Effortless Operation with Compact Size and Lightweight Design: Maximize operator comfort and streamline integration into any workspace. The small size and lightweight design make this machine exceptionally easy to operate and handle.

Its compact footprint allows for seamless integration into desktop

workstations and production lines, while its lightweight nature

simplifies setup and repositioning.

-

Versatile Needle Compatibility for Diverse Applications: Adapt to a wide range of dispensing requirements. This machine is designed to be widely applicable and can be connected to all kinds of standard needles.

This versatility ensures compatibility with various adhesive

viscosities and application types, allowing you to handle diverse

electronic component assembly tasks with a single, adaptable machine.

-

Integrated R Axis for Enhanced Application Flexibility (Glue Dispenser with R Axis): Expand your dispensing capabilities with the integrated R Axis functionality. Named "Glue Dispenser with R Axis", this machine suggests the inclusion of a rotational axis (R-axis). This feature likely enables rotational dispensing,

allowing for applications such as circular patterns, dispensing around

cylindrical components, or precise angular positioning of the dispensing

needle. This added axis enhances the machine's versatility and allows

for more complex and specialized dispensing patterns required in certain

electronic assemblies. (Further clarification on the specific capabilities of the R-axis would be beneficial in a more detailed specification sheet).

-

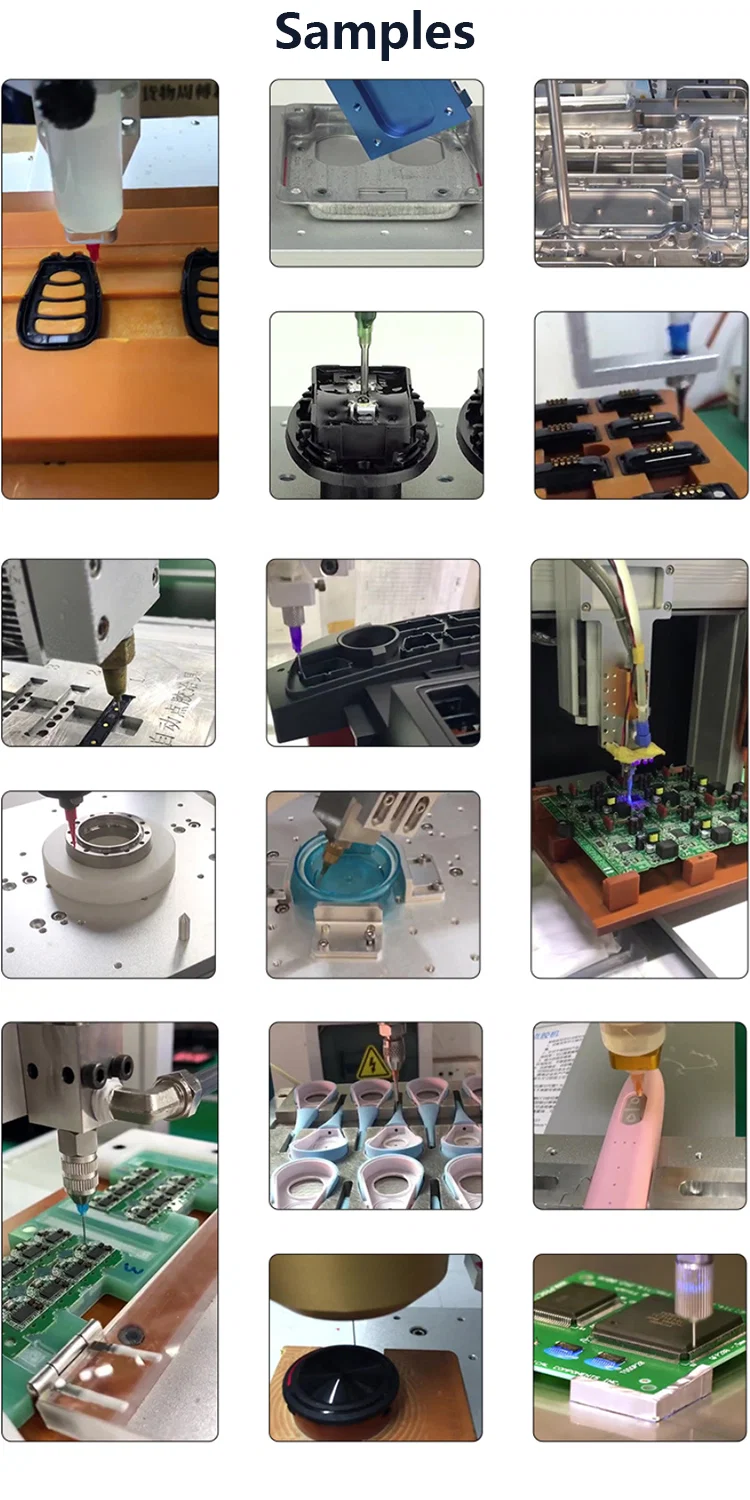

Precise Bonding, Filling, Sealing, Dripping, and Coating for Electronic Components: Engineered for the specific demands of electronic component manufacturing. This machine excels at applying glue and other liquids with precision for a variety of crucial electronic assembly processes, including:

-

Precise Bonding: Securely bonding electronic components to PCBs and housings.

-

Accurate Filling: Filling gaps and cavities with adhesive for insulation and protection.

-

Reliable Sealing: Creating airtight and waterproof seals for sensitive electronic devices.

-

Controlled Dripping: Applying precise droplets of adhesive for micro-bonding and component attachment.

-

Uniform Linear/Arc-Shaped/Circular Coating: Applying consistent coatings for protection, insulation, and environmental sealing of electronic assemblies.

-

Optimized for Electronic Industry Applications: Specifically tailored to the needs of the electronic manufacturing sector. This Desktop Automatic Hot Melt Glue Dispensing Machine For Electronic Industry and Melt Glue Dispensing Machine For Electronic Industry are clearly targeted for applications within the electronics industry,

emphasizing its suitability for the delicate and precise nature of

electronic component assembly and manufacturing.

Technical Specifications:

| Product Name | Glue Dispenser with R Axis |

| Working Pressure | 4-7kg/cm² |

| Operating Viscosity | 1-1,000,000cps |

| Feed Pressure | <10kg |

| Glue Amount (Minimum) | 0.01ml |

| Product Material | Aluminum alloy |

| Product Weight | 30-50kg |

Applications:

This

Desktop Automatic Hot Melt Glue Dispensing Machine is ideally suited

for a wide range of electronic industry applications, including:

-

PCB (Printed Circuit Board) Assembly: Precise bonding and encapsulation of components, application of solder paste, and conformal coating.

-

Semiconductor Packaging: Chip bonding, wire bonding encapsulation, and precise adhesive application in semiconductor device manufacturing.

-

Consumer Electronics Manufacturing: Bonding components in smartphones, laptops, tablets, and other consumer electronic devices.

-

Automotive Electronics Assembly: Reliable adhesive application for electronic control units (ECUs), sensors, and other automotive electronic components.

-

LED Lighting Manufacturing: Precise adhesive application for LED die bonding, lens attachment, and environmental sealing of LED lighting products.

-

Sensor Manufacturing: Accurate and consistent adhesive application for sensor assembly and

encapsulation, ensuring sensor performance and environmental protection.

-

Any electronic manufacturing process requiring precise, repeatable, and reliable adhesive dispensing.

Conclusion:

The Desktop Automatic Hot Melt Glue Dispensing Machine is an indispensable tool for electronic manufacturers seeking to

elevate their assembly processes. Its high precision, robust durability,

user-friendly operation, and specialized features for electronic

applications make it a smart investment for enhancing product quality,

increasing production efficiency, and reducing operational costs. Upgrade your electronic assembly line today with this advanced

dispensing solution and experience the difference that automated

precision can bring to your manufacturing operations.