Wire Prefeeder Paying Machine - Compact Versatility for Streamlined Wire Harness Processing

Headline: Optimize Your Wire Processing Line with the Compact and Versatile Wire Prefeeder Paying Machine

Introduction:

In

today's dynamic wire harness manufacturing environment, efficiency and

flexibility are key to maximizing productivity. Introducing the Wire Prefeeder Paying Machine, a compact yet powerful solution designed to streamline your wire feeding processes. This versatile Cable Feeder Device, also known as an Automatic Wire Feeding Machine,

is engineered for seamless integration with a wide range of wire

harness processing equipment. Whether you're using terminal crimping

machines, wire winding machines, wire cutting machines, or wire

soldering machines, this lightweight and adaptable prefeeder ensures a

smooth, controlled, and knot-free wire supply, enhancing the efficiency

of your entire production line.

Key Features and Benefits: Compact Design, Versatile Compatibility, and Intelligent Wire Feeding

This

Wire Prefeeder Paying Machine is packed with features designed to

optimize your wire processing workflow and deliver superior results:

-

Universal Compatibility with Wire Harness Processing Equipment: Experience seamless integration with your existing machinery. This Wire Prefeeder Paying Machine is designed for broad compatibility, working effectively with a wide range of wire harness processing equipment, including:

-

Fully Automatic Terminal Crimping Machines: Providing a consistent and controlled wire feed for precise terminal crimping operations.

-

Wire Winding Machines: Ensuring a smooth and tangle-free wire supply for efficient coil winding processes.

-

Wire Cutting Machines: Delivering wire at a constant rate for accurate and repeatable wire cutting.

-

Wire Soldering Machines: Maintaining a steady wire feed for automated soldering processes, enhancing soldering efficiency and quality.

This

versatile compatibility makes the Wire Prefeeder Paying Machine a

valuable addition to any wire harness manufacturing facility.

-

Compact and Lightweight Design for Easy Integration and Portability: Maximize your workspace utilization and enjoy effortless integration. The machine's compact and lightweight design, weighing only 8.8kg,

allows for easy placement on workstations or integration into existing

production lines without requiring extensive floor space or complex

installation procedures. Its portability also allows for flexible

repositioning as needed within your facility.

-

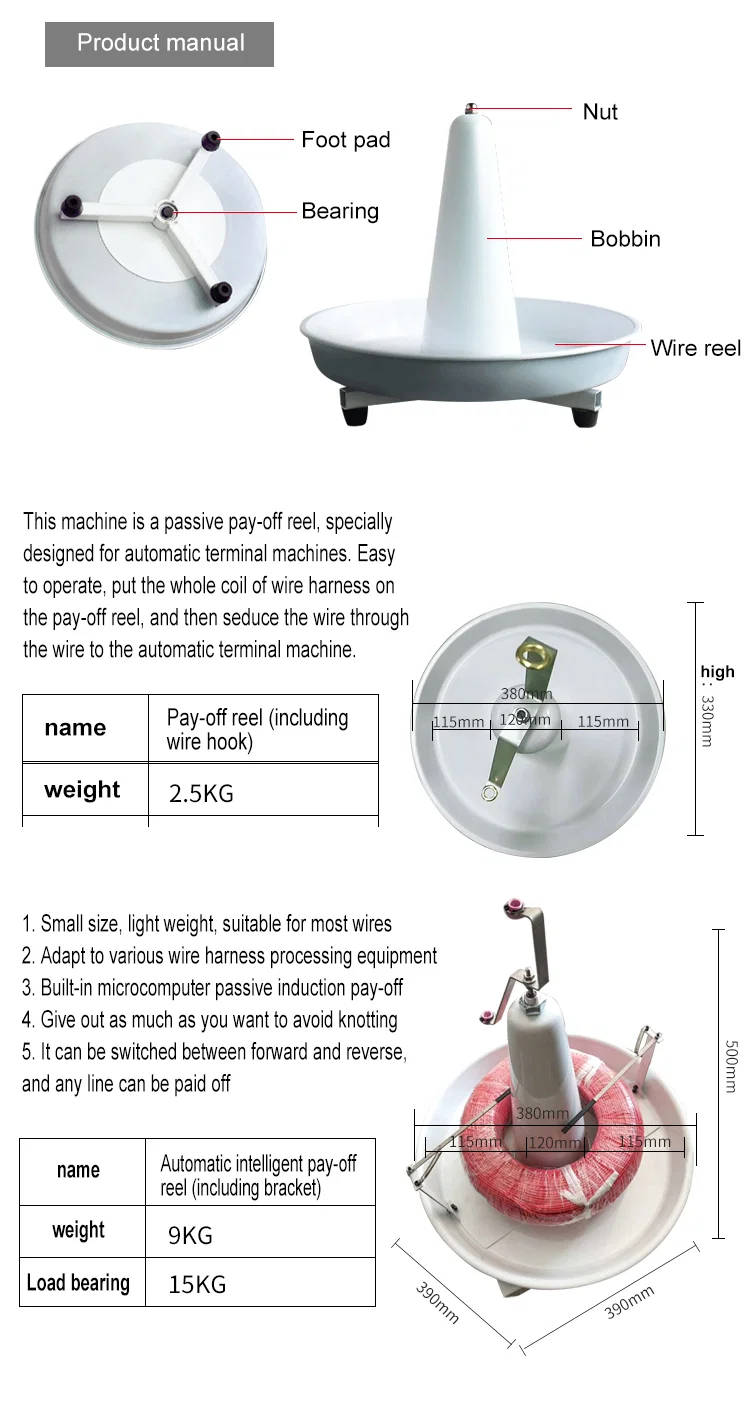

Built-in Microcomputer Inductor for Intelligent Wire Prefeeding: Ensure smooth, tangle-free, and efficient wire delivery. The machine incorporates a built-in microcomputer inductor that intelligently manages wire prefeeding. This advanced system prevents knotting and winding of the wire during the feeding process, guaranteeing a consistent and

uninterrupted wire supply to your downstream processing equipment.

-

Positive and Negative Switching & Arbitrary Feeding for Enhanced Control: Tailor the wire feeding direction and operation to your specific needs. The machine supports positive and negative switching, allowing you to reverse the feeding direction as required for different wire processing setups. Furthermore, arbitrary feeding capabilities provide enhanced control over wire delivery, enabling you

to fine-tune the feeding process to match your specific workflow and

material requirements.

-

Broad Wire Compatibility - Handles All Electric Wires (Excluding Flat Cables): Adapt to a wide range of wire types commonly used in wire harness

manufacturing. This Wire Prefeeder Paying Machine is designed to handle all electric wires,

with the exception of flat cables. This broad compatibility ensures the

machine can be used with the vast majority of wire types used in

standard wire harness production, making it a versatile and practical

solution for diverse applications.

Technical Specifications:

| Weight | 8.8kg |

| Voltage | AC 220V 50Hz |

| Loading Capacity | ≤14kg |

| Rated Power | 0.1kw |

| Suitable Wires | All electric wires except flat cables |

| Operation | Automatic Wire Prefeeding, Automatic Induction |

| Control Features | Positive and Negative Switching, Arbitrary Feeding, Microcomputer Inductor |

| Compatibility | Terminal Crimping Machines, Wire Winding Machines, Wire Cutting Machines, Wire Soldering Machines |

Applications:

The Wire Prefeeder Paying Machine is an essential component for optimizing wire handling and efficiency in:

-

Wire Harness Manufacturing: Streamlining wire feeding for various wire harness assembly processes.

-

Terminal Crimping Operations: Ensuring consistent and tangle-free wire supply for automatic terminal crimping machines.

-

Wire Winding Processes: Providing controlled and smooth wire delivery for efficient coil winding applications.

-

Wire Cutting and Stripping: Delivering wire reliably for precise wire cutting and stripping operations.

-

Automated Wire Processing Lines: Integrating seamlessly into automated wire processing workflows for enhanced efficiency.

-

Any wire processing application requiring compact, versatile, and reliable wire pre-feeding.

Conclusion:

The Wire Prefeeder Paying Machine is a smart investment for businesses seeking to optimize their wire

processing operations and achieve greater efficiency and precision. Its

compact design, versatile compatibility, intelligent wire feeding

system, and user-friendly operation make it an invaluable asset for

modern wire harness manufacturing facilities. Upgrade your wire handling

system today with the Wire Prefeeder Paying Machine and experience the

benefits of truly streamlined and reliable wire pre-feeding.The user

wants me to write very detailed English product descriptions for various

wire processing and cable assembly machines.

For

each machine, I need to create a compelling headline and a detailed

product description highlighting key features and benefits, without SEO

explanations, and focusing on Google indexability and user readability.