WPM-WRD-12Z

Automatic Wire Pre-Feeder Machine - Optimize Your Wire Processing with

Automated, High-Capacity, and Tension-Controlled Delivery

Headline: Maximize

Your Wire Processing Efficiency with the WPM-WRD-12Z Automatic Wire

Pre-Feeder Machine: Seamless Automation, High Capacity, and

Tension-Free Wire Delivery for Uninterrupted Production

Introduction:

In

the demanding world of automated wire processing, ensuring a consistent

and reliable wire supply is crucial for maximizing throughput and

minimizing downtime. Introducing the WPM-WRD-12Z Automatic Wire Pre-Feeder Machine, a cutting-edge solution designed to revolutionize your wire handling processes. This advanced Automatic Pay-off Machine, also known as an Automatic Frequency Conversion Wire Feeder, Four-Axis Pay-off Machine, or Automatic Pay-off Reel,

is engineered to seamlessly integrate with fully automatic computer

wire stripping machines and other wire processing equipment. Eliminate

the bottlenecks of manual wire handling and embrace the future of

automated wire feeding, where the WPM-WRD-12Z delivers a consistent,

tension-controlled wire supply, boosting your production efficiency and

ensuring smooth, uninterrupted operation.

Key Features and Benefits: Automation, Versatility, and Precision Wire Delivery

The

WPM-WRD-12Z Automatic Wire Pre-Feeder Machine is packed with features

designed to optimize your wire processing workflow and deliver superior

results:

-

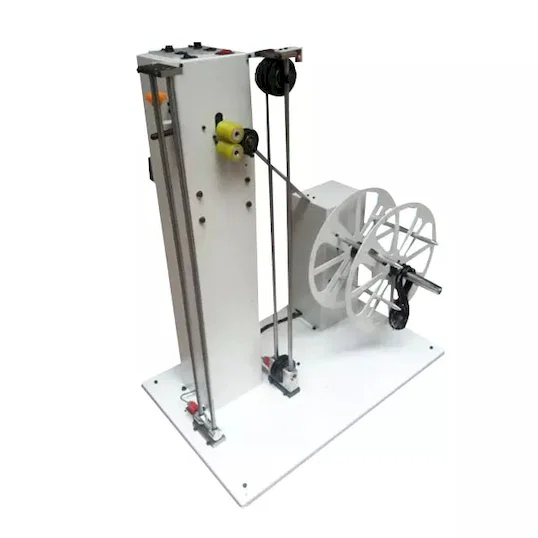

Seamless Integration with Fully Automatic Wire Processing Machines: Experience effortless compatibility with your existing automated equipment. This Wire Pre-feeder machine is specifically designed to work in perfect harmony with fully

automatic computer wire stripping machines and other wire harness

processing equipment. Integrating the WPM-WRD-12Z ensures a synchronized

and efficient automated workflow, optimizing your entire production

process.

-

Automated Wire Feeding - Eliminates Manual Alignment Hassles: Boost your productivity and reduce manual labor. The WPM-WRD-12Z provides automatic wire feeding,

eliminating the need for manual wire alignment and constant operator

intervention. This automation frees up valuable operator time, reduces

fatigue, and allows your workforce to focus on other critical tasks,

significantly increasing overall production efficiency and streamlining

your workflow.

-

Tension-Controlled Wire Delivery for Optimal Processing Quality: Guarantee consistent wire tension and prevent wire damage for superior processing results. The tension sensor can automatically detect wire tension,

ensuring that the wire is always delivered to your wire processing

machine in a state of controlled and consistent tension. This prevents

wire slack, tangling, stretching, and breakage, which are common issues

with manual wire handling and can negatively impact the quality and

precision of downstream wire processing operations.

-

Automatic Start and Stop Functionality - Intelligent and Responsive Operation: Experience truly automated and responsive wire feeding. The machine features automatic start and stop functionality. When wire tension increases, indicating demand from the processing machine, the feeding motor starts automatically. When wire tension relaxes to a pre-set degree, indicating sufficient wire supply, the machine automatically stops.

This intelligent and responsive system ensures wire is delivered only

when needed, preventing overfeeding and maintaining optimal wire tension

throughout the production process.

-

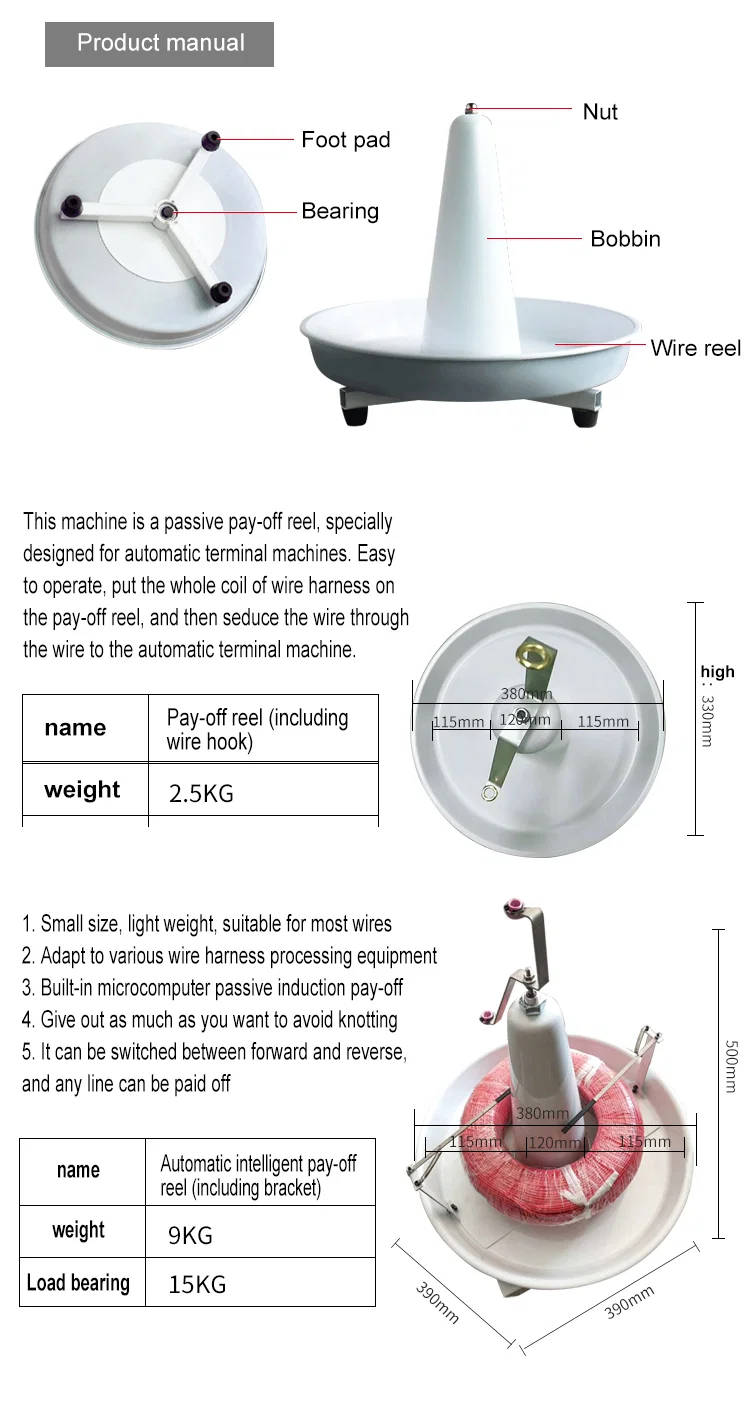

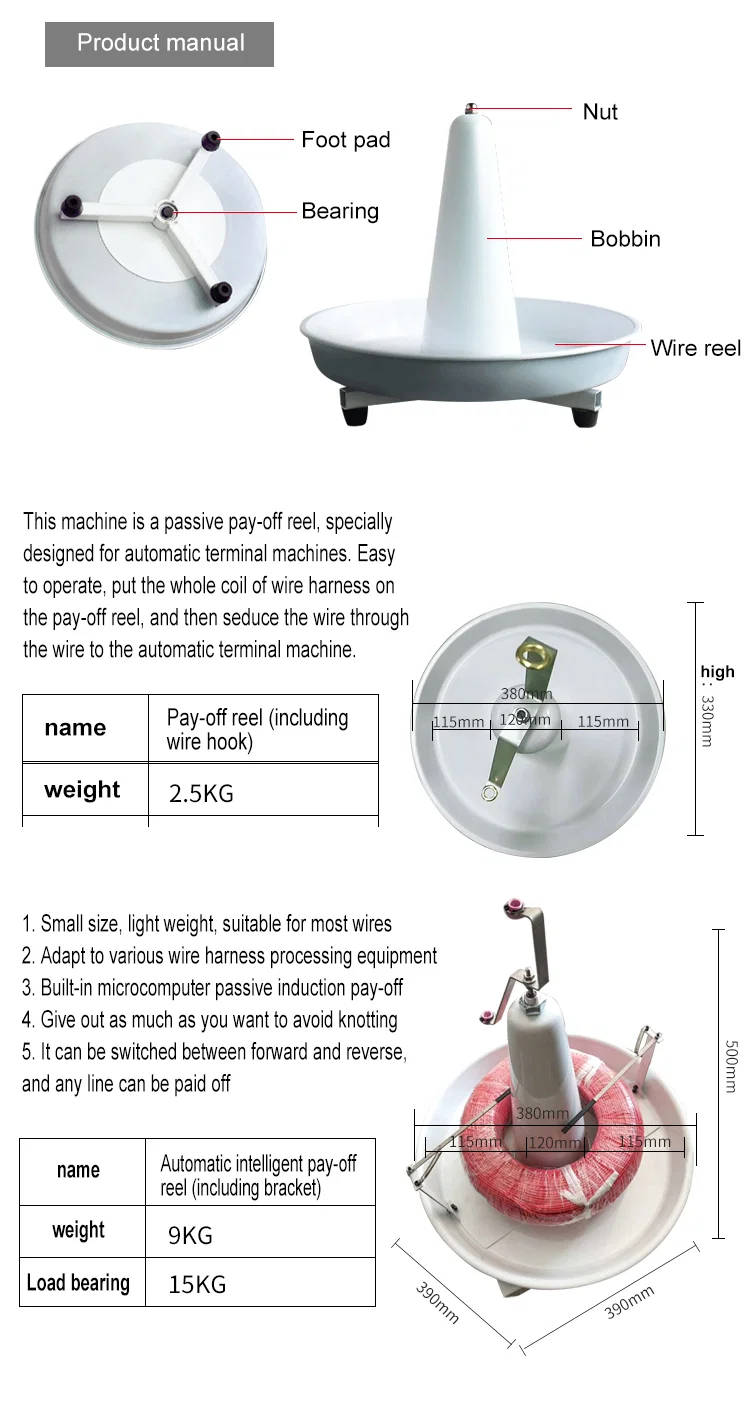

Versatile Spool Compatibility - Handles Wire with and Without Core Winding: Adapt to various wire packaging formats for maximum flexibility. The WPM-WRD-12Z is designed to handle wire spools both with and without core winding. This versatility ensures compatibility with your preferred wire

purchasing and storage methods, allowing you to use a wider range of

wire types and spool configurations without requiring specialized

equipment or modifications.

-

Handles Large and Small Spools - Wide Range of Reel Sizes: Accommodate a diverse range of wire spool sizes for flexible production runs. The machine is designed to handle spools with:

-

Maximum Weight: Up to 35kg, accommodating large wire spools for extended production runs.

-

Minimum Inner Diameter (Core Winding): 30mm, ensuring compatibility with smaller core sizes.

-

Maximum Outer Diameter (Core Winding): 350mm, handling larger diameter spools for reduced changeovers.

This wide range of spool compatibility makes the WPM-WRD-12Z a highly adaptable solution for various wire processing needs.

-

Stepless Speed Regulation for Fine-Tuned Wire Delivery: Optimize wire feeding speed for different wire types and processing requirements. The WPM-WRD-12Z offers stepless speed regulation,

allowing for precise adjustments to the wire feeding speed. This

fine-tuned control enables you to optimize the machine's performance for

different wire gauges, materials, and processing machine speeds,

ensuring smooth and efficient wire delivery across diverse applications.

-

Forward and Reverse Rotation Capability for Enhanced Handling: Adapt to various wire payout directions and streamline setup. The machine supports forward and reverse rotation,

providing flexibility in wire payout direction. This feature simplifies

machine setup and allows you to optimize wire path and integration with

your existing production line layout.

Technical Specifications:

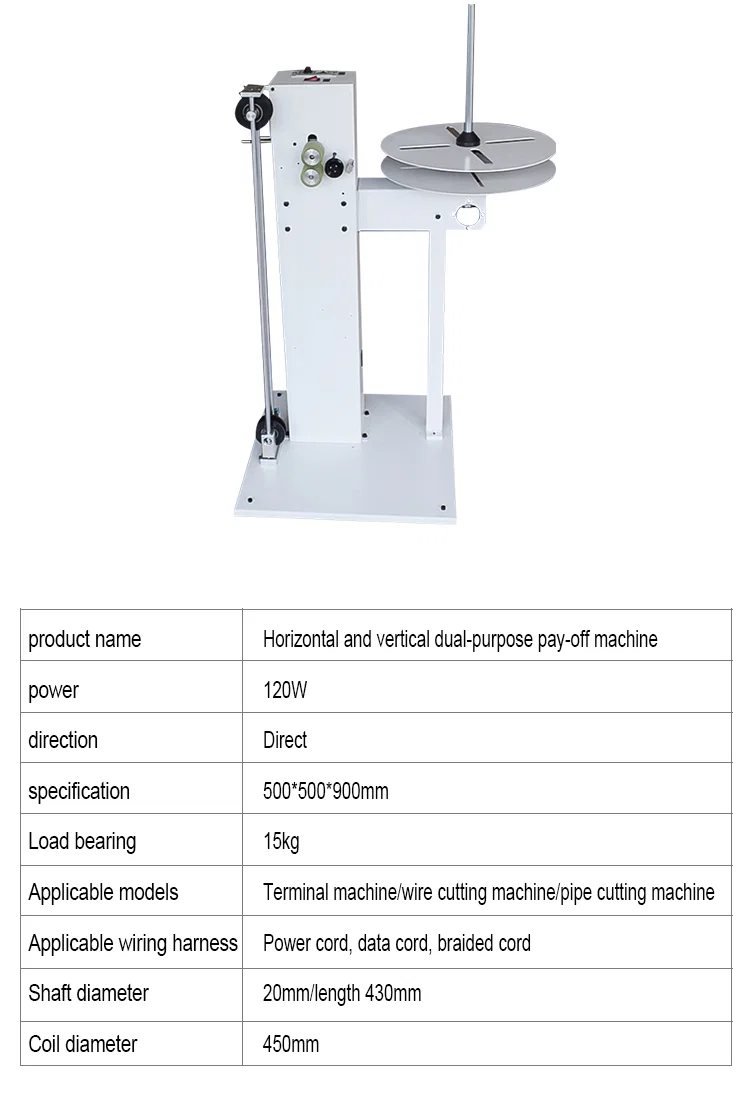

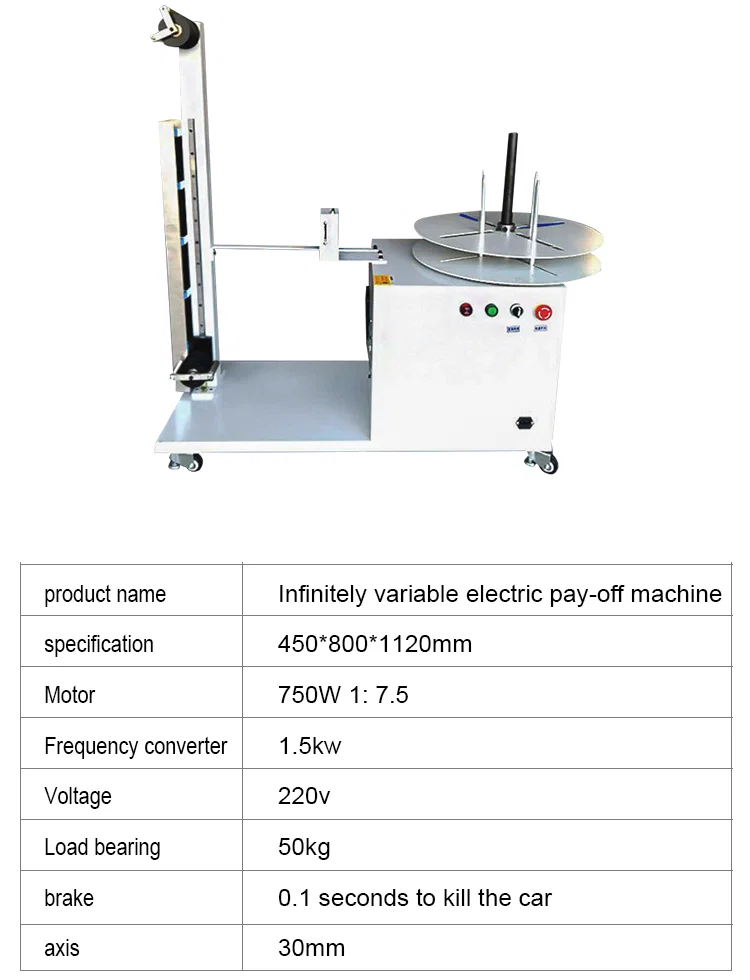

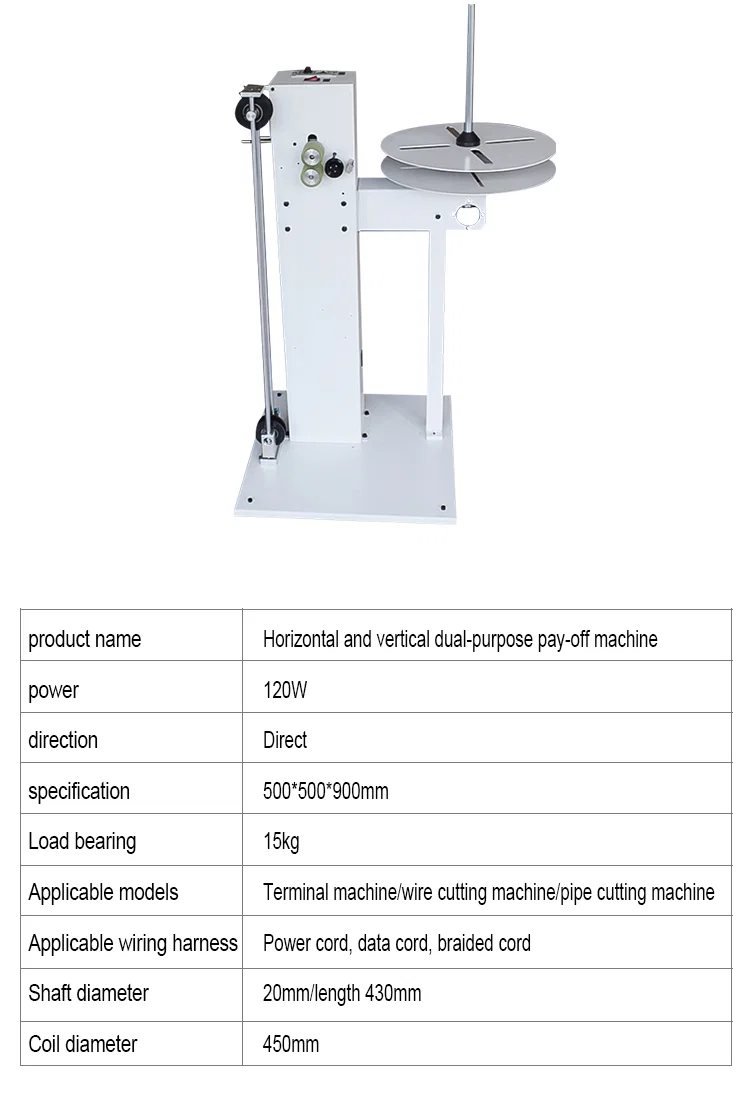

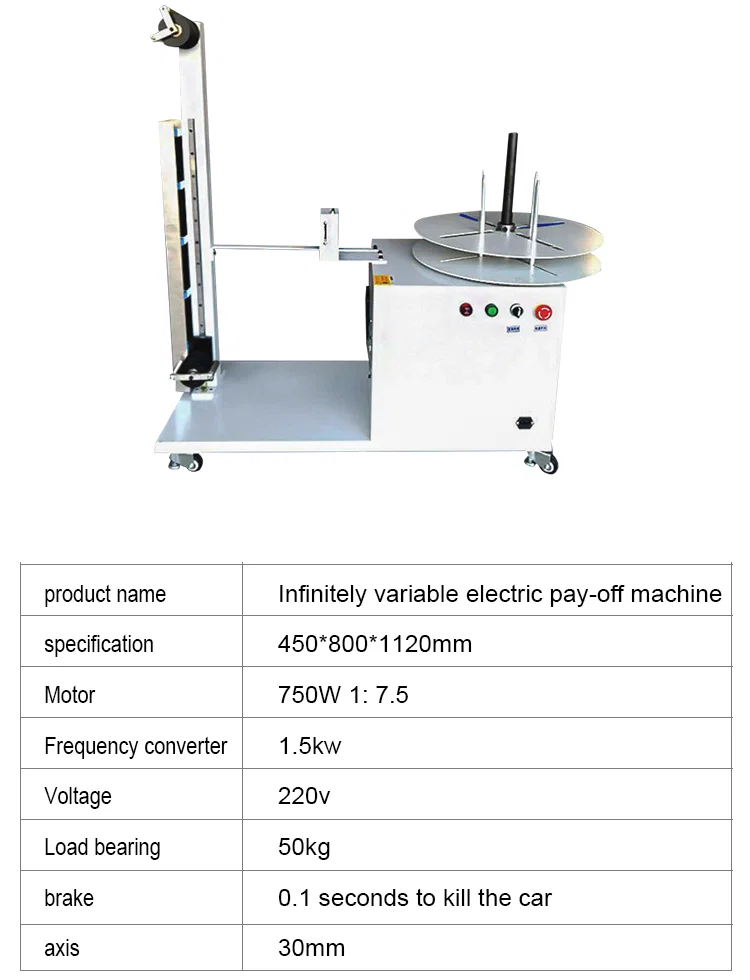

| Name | Pay-off Machine WRD-12Z, Pay-off and Take-up Machine for Wire Drawing |

| Max. Spool Weight | 35kg |

| Reel Type Compatibility | With / Without Core Winding (OK) |

| Min. Inner Diameter of Reel | 30mm (Core Winding) |

| Max. Outer Diameter of Reel | 350mm (Core Winding) |

| Speed Control | Stepless Speed Regulation |

| Rotation Direction | Forward or Reverse Rotation (OK) |

| Tension Control | Line Tight Automatic Alignment, Automatic Stop when Line Relaxation |

| Rated Power | 60W |

| Operating Voltage | 200 to 240V |

| Size (L x W x H) | 300300500mm |

| Operation | Automatic Wire Feeding, Tension-Controlled, Automatic Start/Stop |

| Compatibility | Fully Automatic Computer Wire Stripping Machines, Wire Crimping Machines, Wire Winding Machines, Wire Soldering Machines |

Applications:

The WPM-WRD-12Z Automatic Wire Pre-Feeder Machine is an essential component for optimizing wire handling and efficiency in:

-

Fully Automatic Wire Stripping and Processing Lines: Providing a consistent and tension-controlled wire supply for

automated wire stripping, cutting, crimping, and soldering operations.

-

High-Volume Wire Harness Manufacturing: Ensuring a reliable wire feed for efficient cable harness assembly lines.

-

Cable Assembly Plants: Streamlining wire feeding processes for various cable types and applications.

-

Wire and Cable Manufacturing: Supporting wire drawing and take-up processes with controlled wire tension.

-

Any

wire processing facility seeking to automate wire dereeling, improve

wire delivery precision, and increase overall production efficiency.

Conclusion:

The WPM-WRD-12Z Automatic Wire Pre-Feeder Machine is a smart investment for businesses seeking to optimize their wire

processing operations and achieve significant gains in productivity and

efficiency. Its automated operation, versatile spool compatibility,

tension-controlled wire delivery, and user-friendly design make it an

invaluable asset for modern wire processing facilities. Upgrade your

wire handling system today with the WPM-WRD-12Z and experience the

benefits of truly automated and reliable wire pre-feeding.