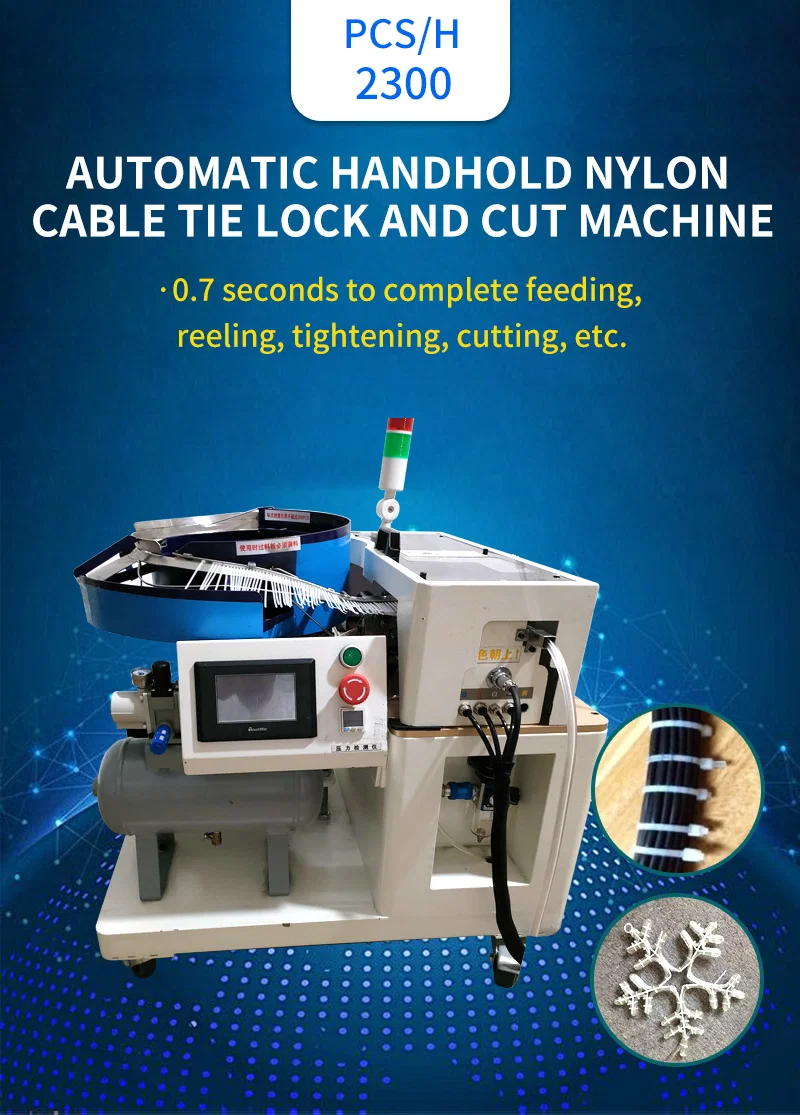

Automatic Handheld Nylon Cable Rolling Machine - Revolutionize Your Cable Bundling Process

Maximize

Efficiency and Consistency in Cable Bundling with the Automatic

Handheld Nylon Cable Rolling Machine: Fast, Reliable, and Versatile

Cable Tie Solution

Introduction:

In

today's demanding manufacturing and production environments,

streamlining cable bundling processes is crucial for efficiency and

organization. Introducing the Automatic Handheld Nylon Cable Rolling Machine, a cutting-edge solution designed to revolutionize your cable tie application. This advanced machine, also known as a Cable Ties Machine, Twist Cable Machine, or Cable Twisted Ties machine,

automates the process of applying nylon cable ties, delivering speed,

consistency, and reduced manual labor. From intricate automotive wiring

harnesses to large-scale construction projects, this machine

significantly enhances your cable bundling workflow, ensuring secure and

professional results every time.

Key Features and Benefits: Speed, Automation, and User-Focused Design

This

Automatic Handheld Nylon Cable Rolling Machine is packed with features

engineered to optimize your cable bundling process and deliver superior

performance:

-

High-Speed Bundling for Increased Throughput: Boost your production output with the machine's impressive speed of 2300 pieces per hour.

This rapid bundling capability significantly reduces cycle times,

allowing you to process more cable bundles in less time, especially

crucial for high-volume production lines and time-sensitive projects.

-

Automated Operation for Reduced Manual Labor and Enhanced Consistency: Minimize operator fatigue and ensure consistent bundling quality with automated cable tie application. This machine automates the nylon cable rolling process,

reducing the need for repetitive manual tying and freeing up operator

time for other tasks. Automated application guarantees consistent

tightness and secure bundling across every cable harness.

-

Versatile Application Scope for Diverse Cable Bundling Needs: Adapt to a wide range of cable bundling requirements with the

machine's versatile design. The machine is suitable for cable ties of 100mm, 120mm, and 150mm in length, and can handle bundling diameters from 1-50mm. This adaptability makes it ideal for diverse applications from delicate wiring harnesses to larger cable bundles.

-

Wide Range of Industry Applications for Broad Utility: Designed for use across numerous industries where cable bundling is essential. The machine is ideally suited for:

-

Automobile Wiring Harness Manufacturing: Streamlining the complex wiring harness assembly in automotive production.

-

Chassis Internal Wiring Harness Assembly: Efficiently managing internal cabling within electronic chassis and enclosures.

-

Christmas Lights Production: Accelerating the bundling of wires for Christmas light sets.

-

Photovoltaic Line Installation: Securing and organizing cables in solar panel and photovoltaic system installations.

-

Assembly-Line Operations: Integrating seamlessly into various assembly lines for enhanced cable management.

-

Building Steel Bar Binding: Adapting for specific applications beyond cabling, such as steel bar binding in construction.

-

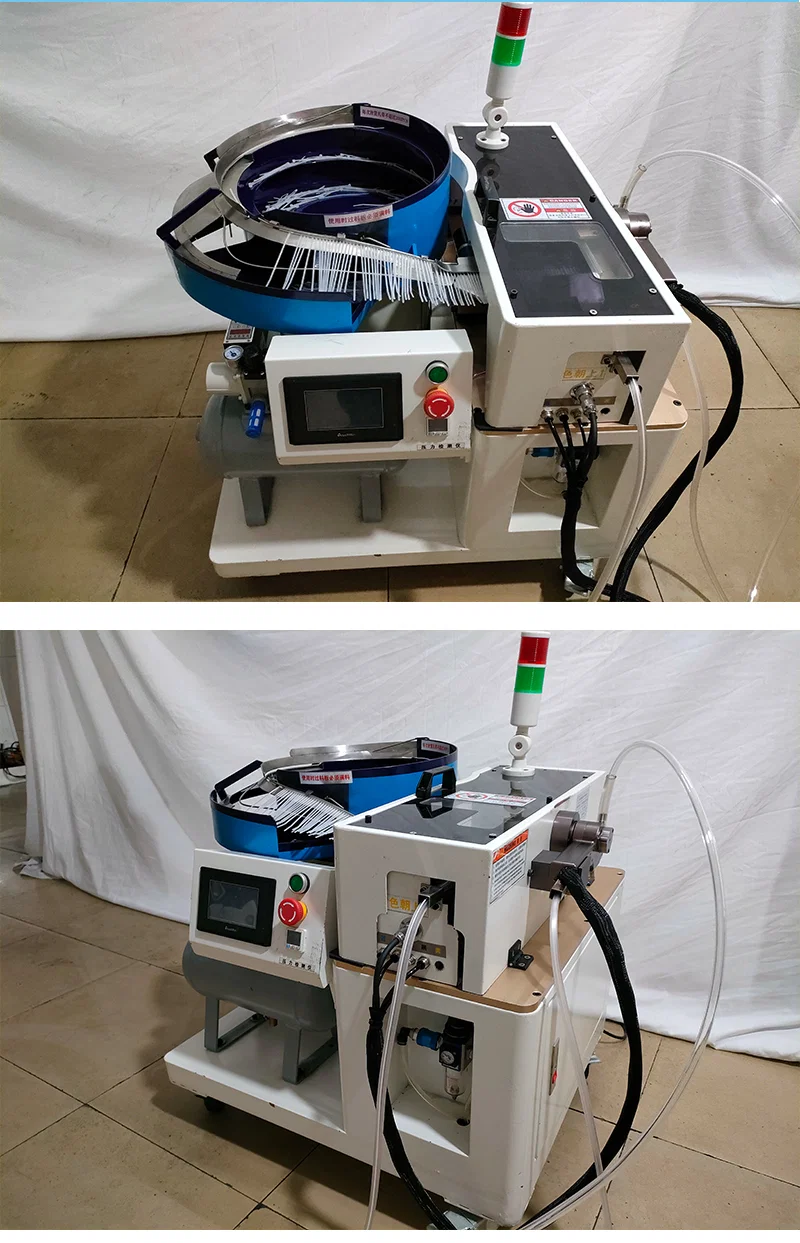

PLC + Touch Screen Control for Intuitive Operation and Adjustments: Experience user-friendly control and precise parameter adjustments with the PLC + Touch screen control system. This intuitive interface allows for easy setup, operation monitoring, and fine-tuning of bundling parameters.

-

Vibration Plate Automatic Feeding for Continuous Material Supply: Ensure a consistent and uninterrupted supply of cable ties with the Vibration plate automatic feeding method.

This efficient feeding system automatically orients and delivers cable

ties to the bundling mechanism, minimizing manual intervention and

maximizing continuous operation.

-

Manually Adjustable Tie Tightness for Customizable Bundling Strength: Tailor the bundling tightness to your specific application needs. The tightness of the tie is manually adjustable,

allowing operators to fine-tune the bundling pressure to accommodate

different cable types and sensitivities, ensuring secure bundling

without damaging delicate wires.

-

Optional Waste Recycling for Environmentally Conscious Operation: Promote sustainability and reduce waste with the optional waste recycling feature. This option allows for the collection and potential recycling of

excess cable tie material, contributing to a more environmentally

responsible and cost-effective operation.

-

Robust and Durable Construction for Industrial Environments: Built to withstand the rigors of demanding industrial settings. The machine's weight of 130 KG and equipment size of 720660780mm indicate a robust and stable construction designed for reliable performance in industrial environments.

Technical Specifications:

| Equipment Size | 720660780mm |

| Weight | 130 KG |

| Equipment Power | 400 W |

| Scope of Application | 100mm/120mm/150mm Cable Ties |

| Equipment Voltage | AC 220V |

| Air Pressure | 0.6mPA+-0.5 |

| Bundling Diameter | 1-50mm |

| Waste Recycling | Optional |

| Speed | 2300 pcs per hour |

| Control Method | PLC + Touch screen |

| Feeding Method | Vibration plate automatic feeding |

| Usage | Automobile

wiring harness, chassis wiring harness, Christmas lights, photovoltaic

line, assembly-line operation, building steel bar binding |

| Tie Tightness | Manually adjustable |

Applications Summarized:

The Automatic Handheld Nylon Cable Rolling Machine is ideal for:

-

Automotive wiring harness assembly

-

Chassis internal wiring harness management

-

Christmas lights manufacturing

-

Photovoltaic system wiring installation

-

General assembly line cable bundling

-

Building steel bar binding (specific adaptation may be required)

-

Any application requiring high-volume, consistent, and efficient nylon cable tie application

Conclusion:

The Automatic Handheld Nylon Cable Rolling Machine is a game-changing solution for businesses seeking to optimize their

cable bundling processes. Its high speed, automated operation,

versatile application scope, and user-friendly controls make it an

invaluable asset for enhancing efficiency, reducing labor costs, and

ensuring consistently high-quality cable bundling in a wide range of

industries. Invest in this advanced cable tie machine and experience a

significant boost in your production throughput and overall operational

efficiency.