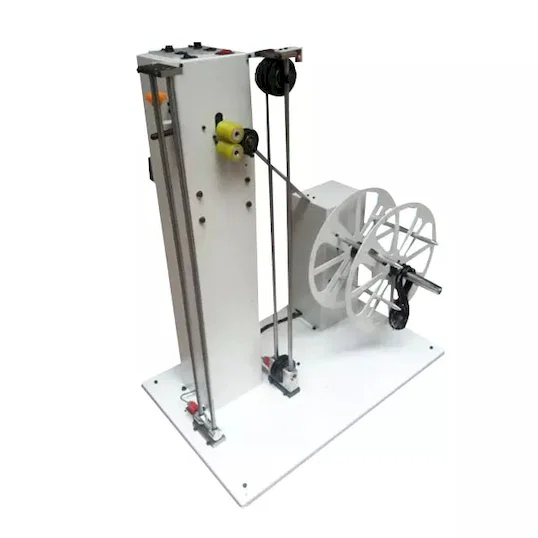

WPM-E005 Five Reels Wire Pre-Feeder Machine - Maximize Throughput and Precision with High-Capacity, Tension-Free Wire Delivery

Headline: Elevate

Your Wire Harness Production with the WPM-E005 Five Reels Wire

Pre-Feeder Machine: Unleash High-Capacity, Tension-Free, and Continuous

Wire Delivery for Uninterrupted Processing

Introduction:

For

high-volume wire harness manufacturing, maintaining a constant and

reliable wire supply is paramount to maximizing production efficiency

and ensuring consistent quality. Introducing the WPM-E005 Five Reels Wire Pre-Feeder Machine, a cutting-edge, high-capacity solution designed to revolutionize your wire handling processes. This advanced Wire Pre feeder Machine is engineered to deliver gentle and continuous wire feeding for even the most demanding automated wire harness processing lines. Featuring five independent wire feeding reels,

active wire storage, and a sophisticated tension control system, the

WPM-E005 guarantees a smooth, uninterrupted, and precision wire supply,

significantly boosting your throughput and minimizing downtime.

Key Features and Benefits: High Capacity, Tension-Free Precision, and Intelligent Automation

The

WPM-E005 Five Reels Wire Pre-Feeder Machine is packed with features

engineered to optimize your wire processing workflow and deliver

superior results:

-

High-Capacity Five Reel System for Uninterrupted Production Runs: Maximize your production uptime and minimize reel changeovers. This five-station wire pre-feeding machine allows you to load up to five wire reels simultaneously. This

exceptional capacity significantly reduces downtime associated with

frequent reel changes, enabling extended, uninterrupted production runs

and dramatically increasing your overall throughput in high-volume

manufacturing environments.

-

Tension-Free Wire Delivery for Optimal Processing Quality: Guarantee consistent wire tension and prevent wire damage for superior processing results. The WPM-E005 is engineered for tension-free wire pre-feeding,

ensuring that wire is delivered gently and continuously to the active

wire storage. This controlled and relaxed wire delivery is crucial for

maintaining wire integrity, preventing stretching, breakage, and

ensuring optimal performance in downstream wire processing operations.

-

Continuous and Active Wire Feeding for Seamless Automation: Experience truly automated wire handling and seamless integration with your production line. The WPM-E005 provides continuous wire feeding to the active wire storage. This active feeding system ensures a

constant and readily available wire supply for your fully automatic wire

harness processing machines, eliminating bottlenecks and maximizing the

efficiency of your automated production line.

-

Independent Motors for Each of the Five Reels - Enhanced Flexibility and Control: Benefit from individual reel control and enhanced operational flexibility. Each of the five wire feeding reels is driven by its own independent motor.

This sophisticated design allows each reel to operate independently,

providing enhanced control over wire feeding and enabling the machine to

handle different wire types or sizes simultaneously, offering

exceptional versatility and adaptability to diverse production needs.

-

Moveable Dancer Pulley System - Adapts to Intermittent Start/Stop Actions: Ensure consistent wire tension even with fluctuating demands from downstream equipment. The WPM-E005 features a moveable dancer pulley. This intelligent mechanism allows the pre-feeder to easily respond to the typical intermittent starting and stopping actions associated with automatic wire processing machines. The dancer pulley

dynamically adjusts wire payout, maintaining consistent tension and

preventing wire slack or tangling, even during stop-start operation

cycles.

-

Active Wire Storage - Buffer for Smooth and Uninterrupted Workflow: Minimize disruptions and ensure a smooth, continuous workflow with the active wire storage feature. The WPM-E005 feeds wire gently and continuously into an

active wire storage area. This storage acts as a buffer, ensuring that

there is always wire readily available for the intake of the fully

automatic wire harness processing machine, preventing delays and

maintaining a consistent and uninterrupted production flow. The storage capacity is approximately 1 meter, providing ample buffer for most applications.

-

Versatile Wire Compatibility - Handles Wire Reels and Loose Coils: Adapt to different wire packaging formats for maximum flexibility. The WPM-E005 is designed to handle both wire reels and loose coils,

providing compatibility with various wire delivery methods. This

versatility ensures the machine can seamlessly integrate into your

existing wire handling infrastructure and accommodate your preferred

wire purchasing and storage practices.

-

Wide Range of Available Wire Diameters for Diverse Applications: Process a broad spectrum of wire gauges with a single, adaptable machine. The WPM-E005 is designed to handle an available wire diameter range of Φ0.5~4mm.

This wide range ensures compatibility with various wire types and

gauges commonly used in wire harness manufacturing, making it a

versatile and practical solution for diverse production needs.

-

Handles Ribbon Cable up to 25mm Width for Specialized Applications: Extend your wire processing capabilities to include ribbon cables. In

addition to round wires, the WPM-E005 can also accommodate ribbon cable with a maximum width of 25mm,

further expanding its versatility and allowing you to process a wider

range of cable types, including specialized ribbon cable assemblies.

-

Accommodates Large Wire Spools for Extended Production Runs: Minimize downtime for spool changes and maximize continuous operation. The WPM-E005 is designed to handle wire spools with a maximum diameter of 350mm and a maximum width of 250mm, and a maximum spool weight of 20Kg. This high capacity allows for the use of larger wire spools, reducing

the frequency of spool changes and ensuring longer, uninterrupted

production runs, further enhancing efficiency and minimizing operator

intervention.

Technical Specifications (Model WPM-E005):

| Model | WPM-E005 |

| Available Wire Diameter | Φ0.5~4mm |

| Ribbon Cable Max. Width | 25mm |

| Wire Spool Diameter (Max.) | 350mm |

| Wire Spool Width (Max.) | 250mm |

| Wire Spool Weight (Max.) | 20Kg |

| Storage Capacity | about 1m |

| Power Rating | 650W |

| Power Supply | 220V 50/60Hz |

| Net Weight | 130Kg |

| Dimensions (L x W x H) | 900×800×1250mm |

| Feeding Mechanism | Five Wire Feeding Reels, Independent Motors |

| Wire Handling | Tension-Free, Continuous, Active Storage |

| Wire Straightening | Implied through Tension-Free design (though not explicitly stated) |

| Control System | Moveable Dancer Pulley for Demand Response |

| Wire Compatibility | Wire Reel or Loose Coil, Electrical Wires, Flat Cables, Sheathed Cables, Steel Wires |

Applications:

The

WPM-E005 Five Reels Wire Pre-Feeder Machine is an essential component

for optimizing wire handling and boosting efficiency in:

-

Fully Automatic Wire Harness Production Lines: Providing a high-capacity, reliable, and tension-free wire supply for automated wire harness assembly.

-

High-Volume Wire Processing Facilities: Meeting the demands of high-throughput wire cutting, stripping, crimping, soldering, and winding operations.

-

Manufacturing of Diverse Wire and Cable Products: Handling a wide range of wire types and gauges, including electrical wires, flat cables, sheathed cables, and steel wires.

-

Any

wire processing application requiring high-capacity, continuous, and

tension-controlled wire feeding for automated machinery.

Conclusion:

The WPM-E005 Five Reels Wire Pre-Feeder Machine is a powerful and versatile solution for businesses seeking to maximize

efficiency and precision in their wire processing operations. Its high

capacity, fully automatic operation, tension-free wire delivery, and

broad wire compatibility make it an invaluable asset for streamlining

your workflow, increasing production throughput, and ensuring

consistent, high-quality wire processing results. Upgrade your wire

handling system today with the WPM-E005 and experience the benefits of

truly automated and reliable wire pre-feeding.