The wire splicing machine is equipped with streamlined internal mechanical parts to reduce wear and replacement. It features a variable frequency motor drive, eliminating conventional clutch operation delay and failure while providing high torque, low vibration, exceptional stability, and ultra-quiet operation.

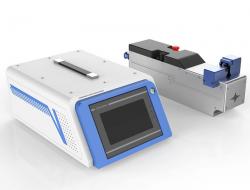

Model WPM-TDJ04M

Capacity 1.5Ton

Stoke 23mm

Applicable copper belt 1-6mm, molds change according to copper belts

Energy consumption

Working 6000times, A kilowatt hour (No load)

Operation Single-action pedal

Motor Asynchronous motor AC220V 550W

Power AC110V/220V 50/60Hz

Measurement 430*430*430mm

Weight 45kg