Wire stripping and cutting machine, Wire Cutting Stripping Machine, Machine For Cutting And Stripping Wires, Automatic Wire Cutting And Stripping Machine Products

Boost Your Wire Processing Efficiency with the Automatic Wire Stripping and Cutting Machine

Introducing the Wire stripping and cutting machine, a fully automated, high-performance solution designed to revolutionize your wire processing operations. This advanced Wire Cutting Stripping Machine, also known as a Machine For Cutting And Stripping Wires, represents the pinnacle of automated wire preparation. As a leading product in Automatic Wire Cutting And Stripping Machine Products, this equipment leverages cutting-edge technology to deliver unparalleled speed, precision, and versatility for a wide range of wire types and applications.

Experience Fully Automated, High-Precision Wire Processing

The Automatic Full Computer Wire Stripping Machine is engineered with advanced automation technology, incorporating innovations from Japan and Taiwan. This numerical control equipment offers a seamless and efficient solution for stripping and cutting wires with exceptional accuracy. Its fully automated operation minimizes manual labor, significantly increasing your production throughput and reducing operational costs.

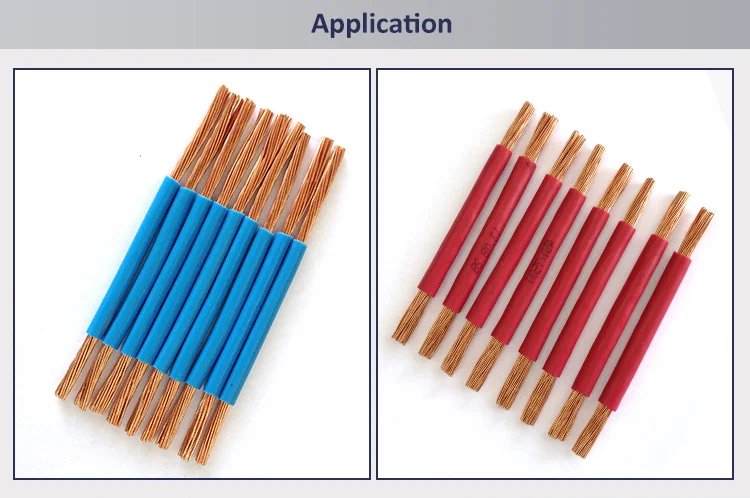

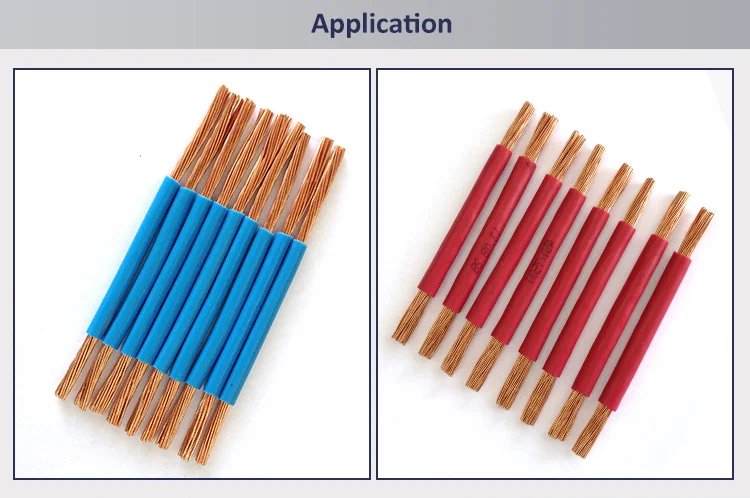

Versatile Applications Across Diverse Industries

This Wire stripping and cutting machine is widely applicable across numerous industries, including electronics, urban infrastructure, electrical appliances, motors, lamps, toys, and various other sectors requiring efficient wire processing. Its versatility extends to the types of wires it can handle, being optimally designed for PVC, Teflon, silica gel line, glass fiber, and similar insulated wires.

Key Features and Benefits of the Wire Stripping and Cutting Machine:

- Fully Automatic Operation: Minimizes manual labor and maximizes production efficiency with complete automation.

- Advanced Automation Technology: Incorporates cutting-edge technology from Japan and Taiwan for superior performance.

- High Precision and Accuracy: Delivers exceptional cutting and stripping accuracy, ensuring consistent results.

- Versatile Wire Compatibility: Processes a wide range of wire types including PVC, Teflon, silica gel line, glass fiber, and electrical wires.

- Broad Application Spectrum: Ideal for electronics, electrical appliances, automotive, toy manufacturing, and many other industries.

- Large Wire Cross-Section Range: Handles wires from 0.1 to 10.0mm² (AWG7# - AWG32#).

- Long Cutting Length Capacity: Cuts wires to lengths from 1mm up to an impressive 100,000mm.

- High Speed and Productivity: Achieves a remarkable production speed of 3000-5000 pieces per hour.

- User-Friendly English LCD Display: Intuitive English LCD interface for easy operation and parameter setting.

- Durable Hard Tungsten Steel Blades: Ensures long-lasting, clean, and precise cutting performance.

- Energy-Efficient Operation: Low power rating of 500W for cost-effective and environmentally conscious operation.

- Compact and Space-Saving Design: Small footprint (390X350X255mm) fits comfortably in various workspaces.

Technical Specifications: Automatic Full Computer Wire Stripping Machine

36kg

| Model | WPM-09D | WPM-09JE | WPM-09JE2 |

| Wire material | PVC, teflon, fiberglass wire... | PVC, teflon, fiberglass wire... | PVC, teflon, fiberglass wire... |

| Conductor cross-section | 0.1 - 8.0 mm² (32 - 8 AWG) | 0.1 - 8.0 mm²(32 - 8 AWG)

Note: BV wire < 4mm² | 0.1 - 10 mm²(32 - 7 AWG)

Note: single-stranded BV < 6 mm²; 7 core BV < 10 mm² |

| Cutting length | 1 - 99,999 mm | 1 - 99,999 mm | 1 - 100,000 mm |

| Cutting length tolerance | 0.002 * L | 0.002 * L | 0.002 * L |

| Stripping length | Side I: 0 - 35 mm Side II: 0 - 15 mm | Side I: 0-50mm Side II: 0 - 50 mm | Side I: 0 - 80 mm Side II: 0 - 80 mm |

| Maximum guide tube diameter | 8 - 10 mm | 8 - 10 mm | 13 mm |

| Productivity | 33 - 83pcs/min | 33-83pcs/min | 50-133pcs/min |

| Noise level | < 70 dB(A) | < 70 dB(A) | < 70 dB(A) |

| Power supply | 110, 220 V (50 - 60 Hz) | 110, 220 V (50 - 60 Hz) | 110, 220 V (50 - 60 Hz) |

| Power | 300 W | 300 W | 500 W |

| Gross Weight | 34 kg | 34 kg | 34 kg |

| Carton dimension | 537 * 507 * 400 mm | 537 * 507 * 400 mm | 537 * 507 * 400 mm |