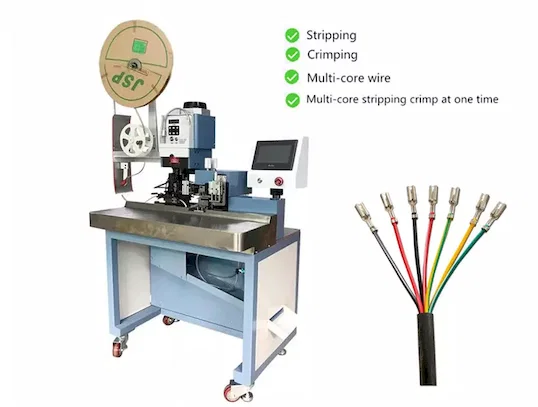

Wires Stripping Crimping Machine, Inner Wires Stripping Crimping Machine

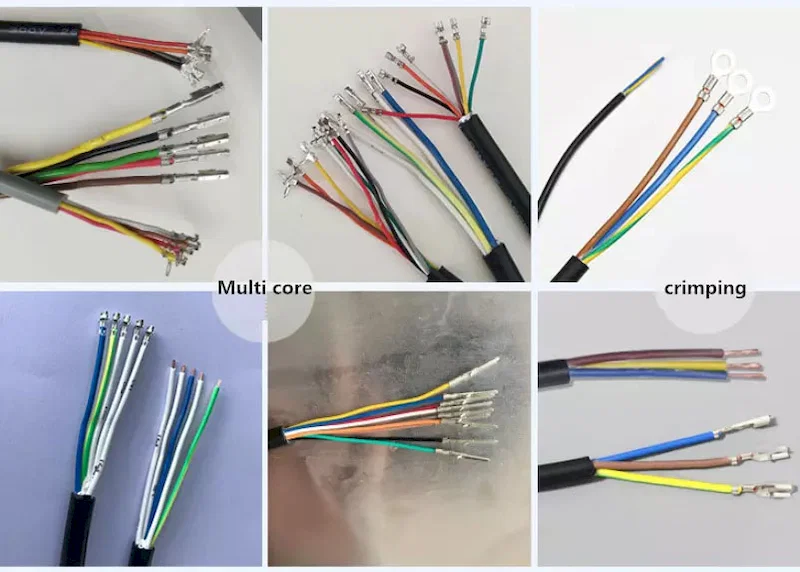

Cable type Multiple conductor cable, flat cable, etc.

Cable outer diameter 1.3 - 32 mm (0.052 - 1.259 inches) (larger cable can be customized)

Conductor size 30 - 16 AWG

Conductor numbers 2 - 20 (depending on the cable type)

Stripping length Depends on conductor size

Crimping force 1.5 T

Applicator OTP

Productivity 3600 pcs. /h (depending on the wire type)

Power supply 110, 220 V (50 - 60 Hz)

Power 750 W

Dimension (L * W * H) 800 * 600 * 1250 mm (31.50 * 23.62 * 49.21 inches)

Net weight 145 kg (319.67 lb)